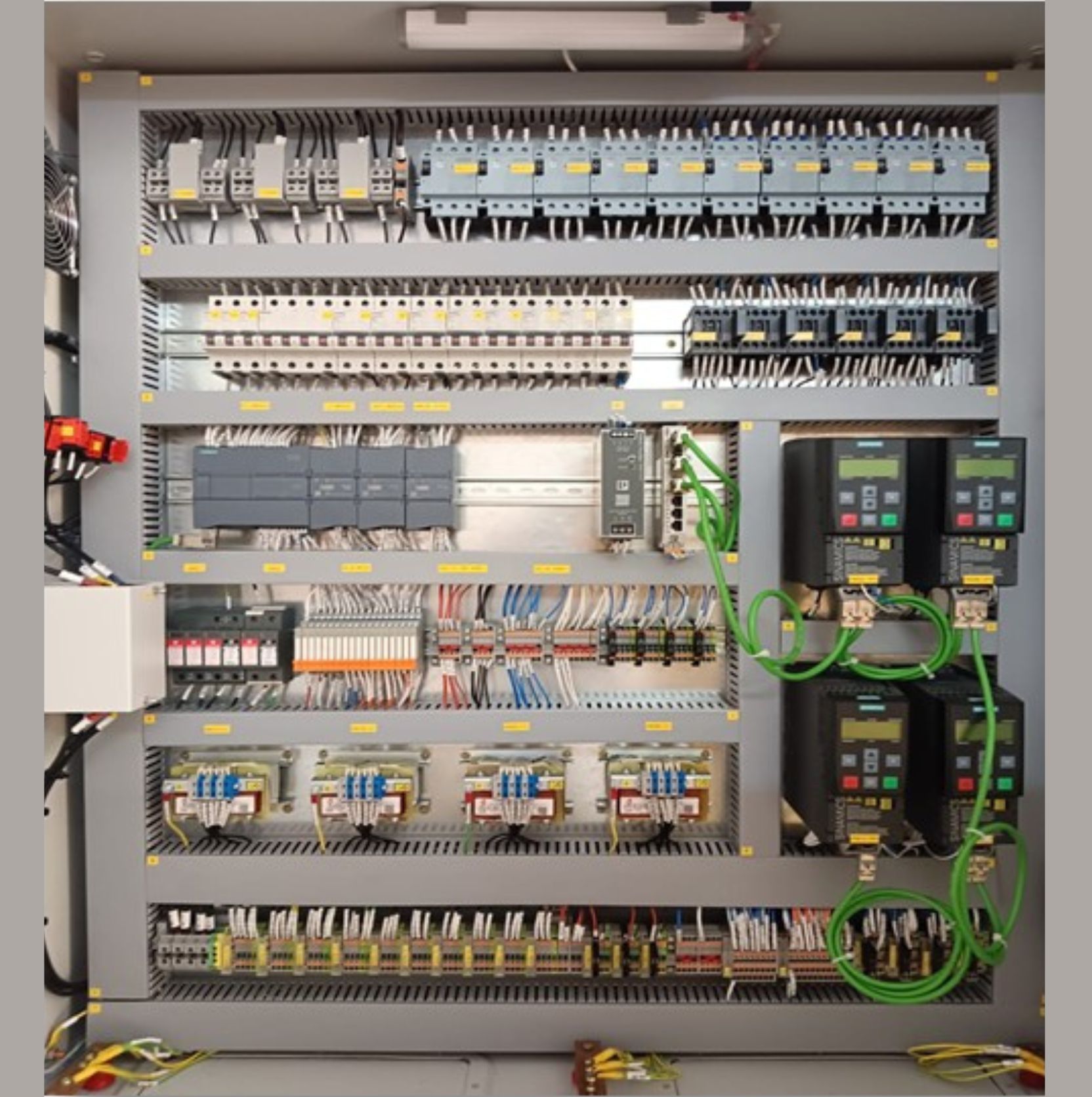

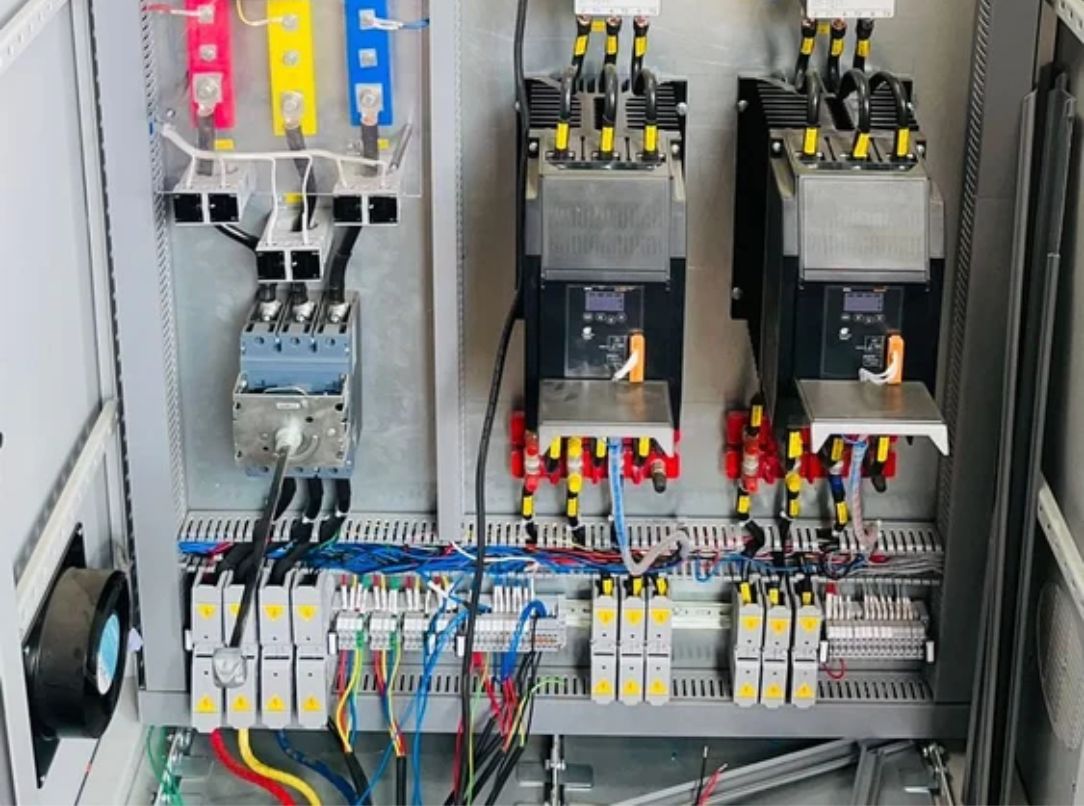

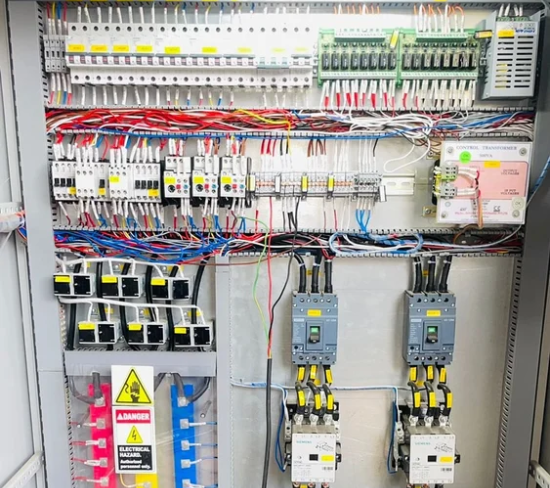

Pump Automation

Pump Automation integrates intelligent control systems and sensors to optimize pump operations, ensuring precise flow control, energy efficiency, and reliable performance. This technology reduces manual intervention, enhances system monitoring, and improves maintenance scheduling, making it ideal for industrial, commercial, and municipal applications.

By utilizing real-time data and automated controls, pump automation systems can adjust operations based on demand, prevent overloads, and detect faults early. This leads to extended equipment life, reduced energy consumption, and minimized downtime, ultimately improving overall process efficiency and cost-effectiveness.

Precise Flow Control

Energy Efficiency

Predictive Maintenance

Enhanced Reliability

Intelligent Pump Control

Intelligent Pump Control leverages advanced automation and real-time monitoring to optimize pump performance, enhance energy efficiency, and ensure reliable operation. By adapting to system demands and enabling predictive maintenance, it minimizes downtime and maximizes productivity across diverse applications.

Adaptive Performance

Proactive Maintenance

System Integration